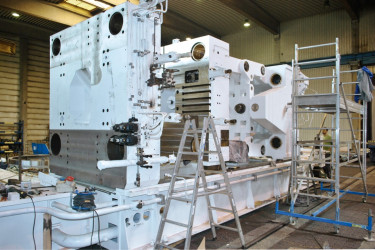

The better your machine is set up, the higher the quality of the production result achieved at the end of processing. Antrok uses state-of-the-art measuring technology for machine inspection and measurement. As part of RetroFit or to optimize your production processes, we install, maintain and align die casting systems in accordance with the strictest quality criteria.

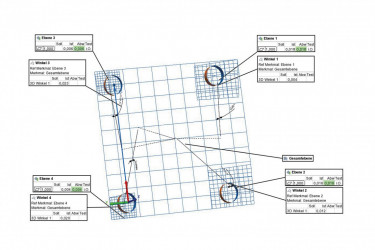

The horizontal measurement and alignment of your system in the machine bed is carried out using a hose scale. The clamping plates are then positioned at an exact angle of 90 degrees and connected to the machine base. The shot is adjusted in our tried-and-tested process using high-precision laser measurement. A rotating laser attached to the piston rod checks individual positions step by step and detects even the smallest deviations with 100% certainty. This data is used to fine-tune the firing unit.