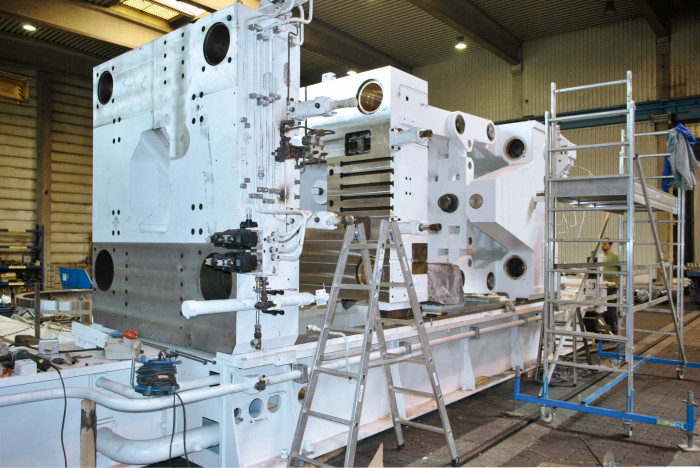

Creeping efficiency losses and new technological developments in production require regular reflection on production efficiency. Only in a few cases does a replacement investment for existing systems really make sense. For all other general overhaul and retrofit tasks, our specialists at Antrok are always at your side.